A new hot lamination process

for demanding technical applications

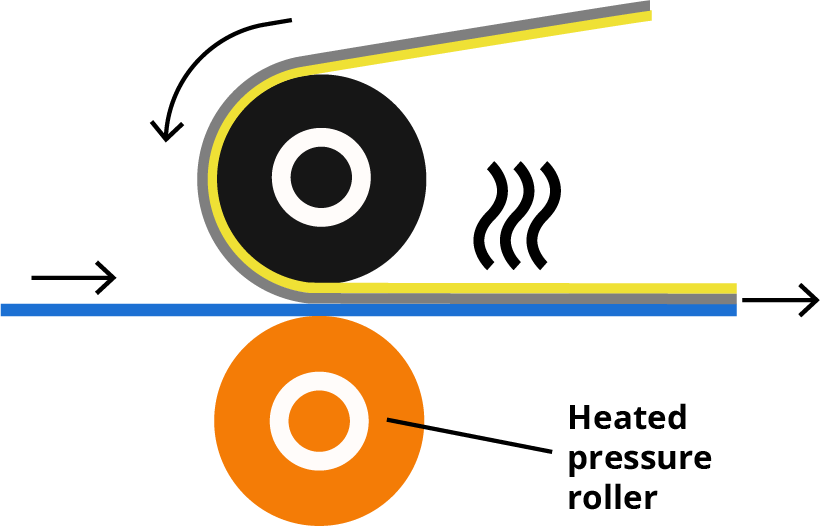

Hot lamination uses heat-activated thermoplastic adhesive films to bond various materials. The film is first applied in its solid state at room temperature, then thermally activated to ensure adhesion. This process enables precise, delayed, and repositionable bonding, ideal for demanding technical applications.

The transformation using heat-reactivable hot-melt films relies on thermoplastic polymer-based adhesive films that are activated by temperature rise.

During the process, the adhesive film is applied to a substrate in solid form and then exposed to controlled heat, causing partial or full melting of the adhesive layer. This melt creates anchorage to the substrate or bonding between multiple layers.

The adhesive becomes tacky only when heated, allowing for delayed bonding and possible repositioning before thermal activation. Once cooled, the system provides optimal cohesion and adhesion.

This process is particularly suited to applications requiring high assembly precision, selective activation, or intermediate storage prior to final bonding.

Materials Processed

Target Markets

Fashion

Construction

Automotive

Furniture

Interior Design

Luxury Goods

Contact

-

17 Rue Edouard Garet

42160 Andrézieux-Bouthéon - +33477426590